Surrogate Modeling for Electronic Component Selection Using Thermal Simulation

Free

This white paper presents surrogate modeling as an advanced, efficient approach to electronic

component selection using thermal simulation. It addresses the critical challenge of balancing

thermal performance accuracy with the significant computational cost of full thermal simulations.

The paper outlines the surrogate modeling methodology, including data generation via high-fidelity

simulations, construction of predictive models using polynomial response surfaces, Gaussian

process kriging, neural networks, and support vector machines, followed by rigorous validation

techniques to ensure model reliability. Key applications demonstrated include optimizing thermal

management in power management ICs, FPGA thermal design, and LED array configurations.

The benefits of surrogate modeling highlighted include drastically reduced simulation times—

orders of magnitude faster than conventional CFD—enabling extensive design space exploration,

seamless integration with automated optimization algorithms, and effective sensitivity analysis.

Limitations such as model accuracy within the training data range and the need for regular

maintenance are also discussed candidly. Implementation best practices recommend integrating

surrogate models into existing CAD environments and establishing continuous validation protocols.

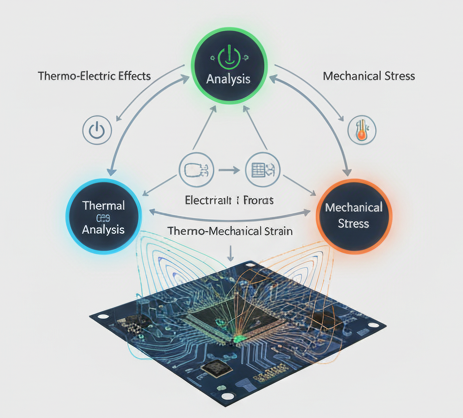

Finally, emerging trends like multi-physics coupling, AI-powered component recommendations,

and active learning loops are presented as future directions that promise to further boost design

efficiency and reliability. Overall, surrogate modeling empowers engineers to achieve thermally

optimized component selections rapidly, meeting aggressive development schedules and delivering

a competitive edge in electronic system design.

Gofinite Ventures LLP

LLPIN : AAU-5144